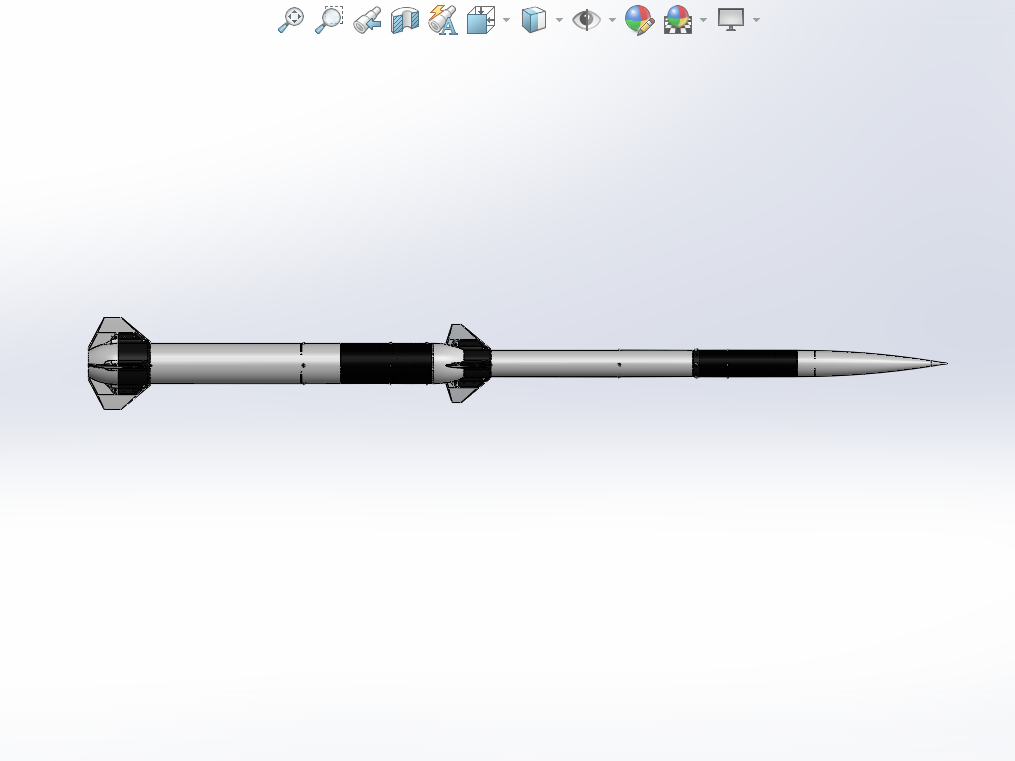

Eagle II v4

A 2-stage 30k ft apogee rocket setting a record for the highest flying rocket designed by students on the East coast.

21' - 21'

* Though fully completed and tested, this project was shut down by Rutgers due to COVID. I was not involved in this project since the beginning, coming in at the later stages to aid mostly in manufacturing. *

Circuitry

Manufacturing

Contribution |

I designed and made the camera system and mount for the rocket. I used SOLIDWORKS to create 2 iterations and manufactured the mount with a single piece of acrylic that was laser cut. I soldered together and tested the system. I constructed the aerobody of the rocket, assembled the recovery system, and soldered the telemetry system. I explained to less experienced teammates how the rocket functioned. |

Improvement |

The Eagle series of rockets already has a set design scheme. It's a very good design and has been what's taken RRPL to such great heights. However, I never understood why we opted for 4 fins instead of 3. A properly designed 3 fin rocket produces far less drag than a 4 fin rocket while maintaining stability, resulting in higher apogee. This could be achieved without compromises in any other component. On a smaller scale, due to time constraints, I opted for a laser-cut camera module for faster manufacturing. I originally designed a component for 3D printing that I believe was superior. The laser-cut design compromised on ease of assembly and structural integrity. Made of acrylic, it was awkward to secure to the interstage and required holes drilled in the side to mount the FPV camera and DVR with screws which often cracked the module. A strong print that would sit snugly into the extruded cut of the interstage and not require additional processing would be the right way to go. |

Material |