Project Supersonic

A rocket engineered to break the sound barrier at Mach 1.35.

19' - 20'

* This rocket blew up in midair. Sadly there is no flight video. You can read more about why in the 'Story' section which is coming soon. *

SOLIDWORKS

Circuitry

3D Printing

Manufacturing

Arduino

Simulaton

Project Management

Specs |

Mach 1.35 Simulated Max Speed 1726 m. Simulated Apogee 40.67 G Simulated Max Acceleration H135W Motor |

Contribution |

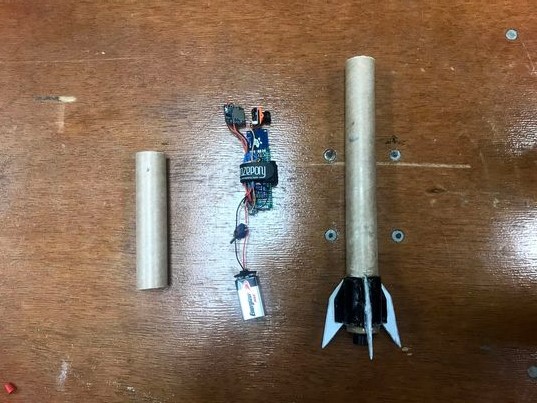

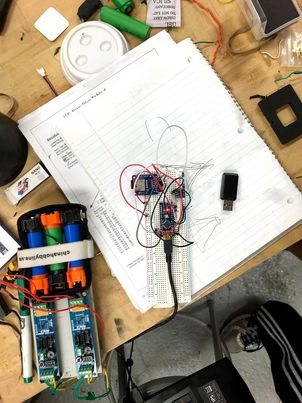

At first glance, you might think what you're looking at isn't that impressive. You might think the rocket looks simple and small. However, it is BECAUSE of the fact that it's simple and small that it is impressive. Every single component needed to be insanely optimized to make the rocket work. For example, the motor Project Supersonic uses would typically be found in a rocket the size of my L1 rocket. I engineered Project Supersonic to be a 'minimum diameter rocket', meaning the motor hugs the body tube with millimeters to spare. By increasing mass in the nose cone and decreasing fin size, we optimized the rocket to reach maximum apogee while maintaining stability while hitting Mach 1.35. To account for the rocket's minimum diameter nature, the telemetry system was soldered onto the smallest PCB board possible, with many connections between the barometric pressure sensor, camera, Arduino, and battery utilizing double-sided solder connections instead of wire. Fin cans also needed to be designed with SOLIDWORKS instead of traditional traditional attachments to secure fins without body tube space. I was responsible for all SOLIDWORKS, manufacturing, and assembly. I managed and worked with my team on the telemetry system and simulation. |

Improvement |

Despite everything, this rocket was ultimately a failure, blowing up in midair. However, I probably learned the more out of this project than anything else I did in high school. There were so many factors that could've changed the outcome, I'll touch on a few. 1. Project management. We didn't slack, but we'd be pulling 7-day work weeks and all-nighters before launch days compared to the regular once or twice a week meetings. If I laid out meetings better, perhaps we would've gotten more done and wouldn't have made some mistakes that costed the mission success. 2. Symmetry. The flight of Project Supersonic took an undesirable spiral shape. I think this was clearly due to my lack of precision when manufacturing the rocket resulting in a lack of radial symmetry. I should've made jigs to ensure precision as the aerobody was epoxied together. I should've balanced the camera cutout with two more. I should've CNCd the fin fillets instead of manually filing them. 3. Patience. Project Supersonic was already greatly delayed and I should've made the call to delay more instead of flying something imperfect. I also was too excited to make progress and permanently attached the motor to the aerobody when I should've saved that step for last such that we could remake the aerobody without wasting the motor. 4. Ejection. Even fixing problems 1-3, Project Supersonic would've been retreivable had ejection been done correctly. I believe the rocket blew up because it burned through the delay grain too quickly. As mentioned, the motor Project Supersonic used is normally for far less impressive flights. The ejection charge went off while the rocket was still in ascent. Not just that, I included too much ejection charge which gave the payload compartment a pressure it could not handle resulting in explosion. There's other things I would improve upon as well but these are a main 4. |

Material |