Machinist

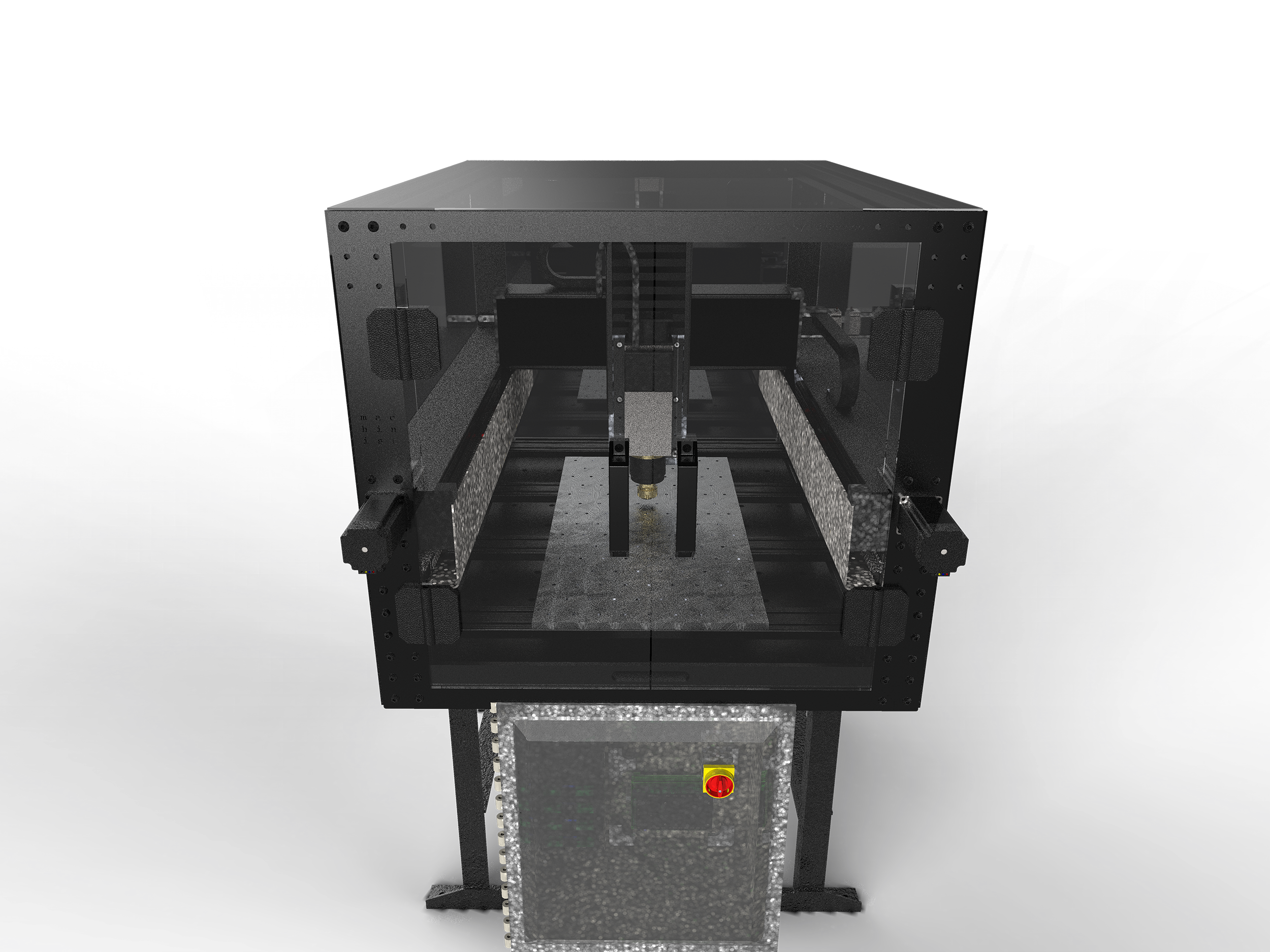

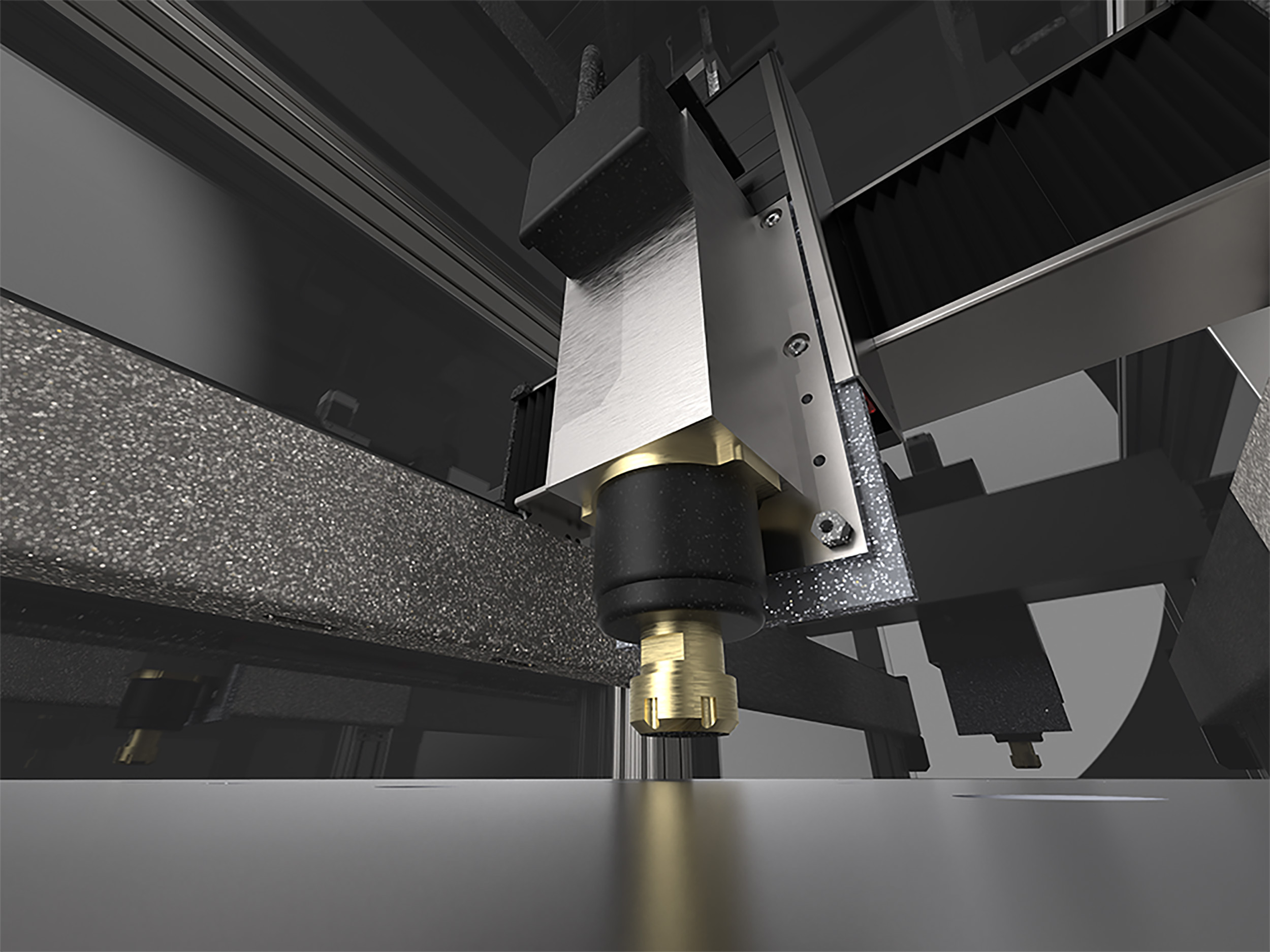

A desktop CNC mill with extreme metal-cutting precision strategically designed to be able to manufacture itself and other thecncco machines.

21' - 22'

SOLIDWORKS

CNC Machining

Circuitry

Keyshot

Specs |

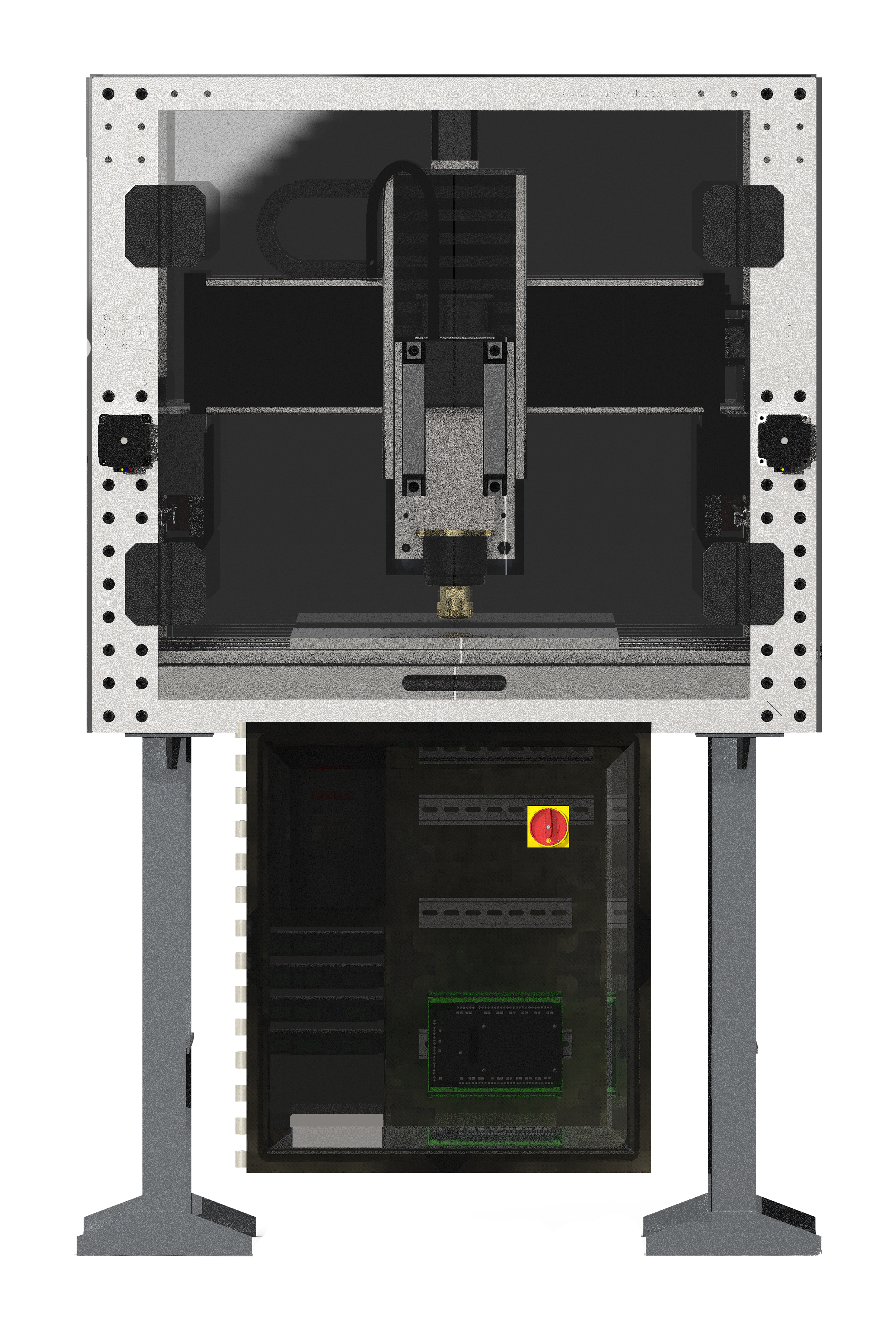

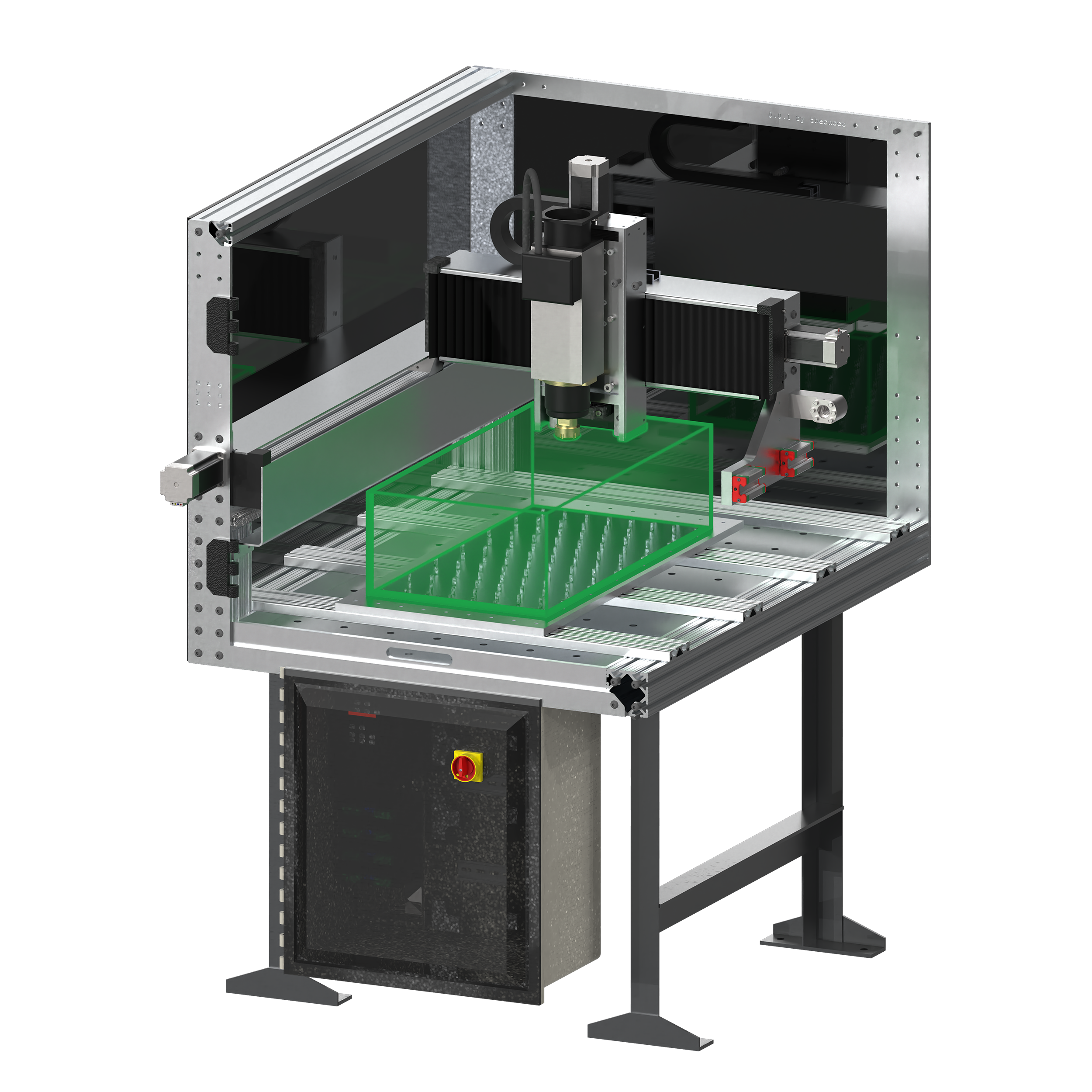

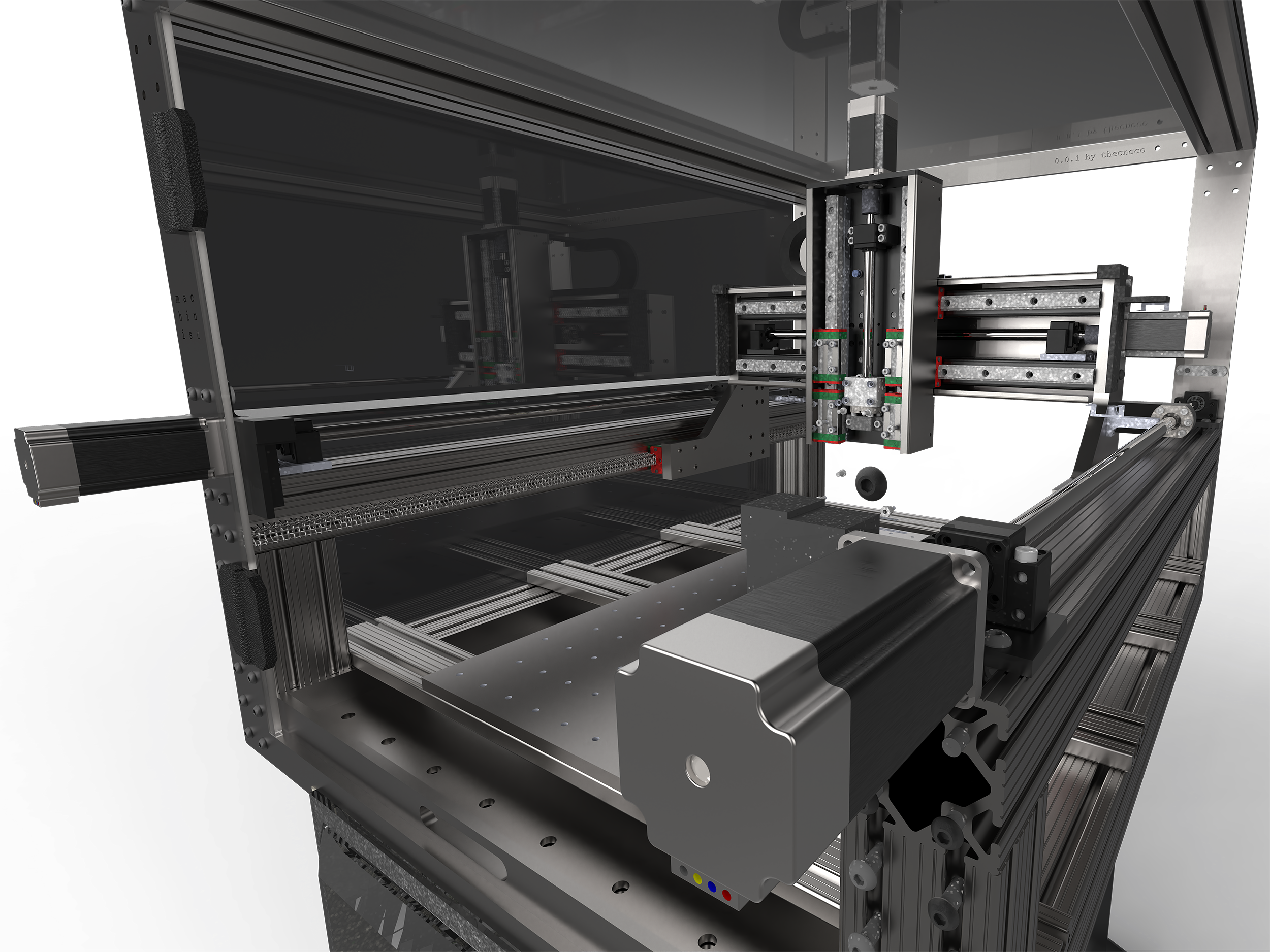

0.00003125 in. Theoretical Max Precision 0.001 in. Maximum Backlash 15 in. x 30 in. x 7 in. Work Area 32 in. x 48 in. x 55 in. Footprint 1.2kN XY Driving Force 2.4kN Z Downwards Force 120 in./min XY Lead Speed 60 in./min Z Lead Speed |

Contribution |

I created the design of the first iteration of Machinist, deemed the 'hanging gantry' design. This version provided three large benefits over other mills: a built-in full enclosure, accessibility of the work surface, and a cohesive, cost-effective design. However, we eventually decided the moment about the rails via the gantry would be too large when carving through metal, almost certainly causing undesirable vibrations, reducing precision. As such, Machinist was adapted for the X-axis rails to have minimum Z distance from the machining surface, reducing the vibration and increasing precision. While the 'hanging gantry' that the first iteration was named after was scrapped, many aspects of the design remained, most notably the integrated enclosure. I didn't work much on iteration 2 besides providing feedback and design ideas until near the end of the CAD process. My design influence focused on finding the simplest way to resolve multiple needs, an example being the dust shields both protecting the X-axis ball screws and providing a surface for the drag chain. In the final stretch of CAD, I made modifications to the frame plates, enclosure, and various gantry components. I also performed quality checks on components to ensure they were fit for purchase and manufacture. I created multiple renders of the machine and prepared marketing material. Besides engineering and design, I also project managed one of the most crucial periods of Machinist's development. Leading up to P-day, or purchase day (the day we would order all components for our prototype), I guided our team to finish the CAD model, quality check every component, and raise money - resulting in one of the most productive sprints in our company's lifetime. I accomplished this by aligning our team to a specific goal, establishing productive rules around work, and creating a custom Agile-esque Kanban board tailored for our needs. |

Improvement |

Although I'm proud of Machinist's design, because we were on a time and budget restriction, there were a few things we overlooked. There's a few things we accounted for but aren't in the design, like properly fitted front panels, and there's a few things we didn't account for, like a built-in zeroing plate. The electrical box is annoying to manufacture, with us needing to create custom openings in a commercial enclosure. We'll need to either design a custom box or create an effective jig to modify the existing box in a more efficient way. However, more than the design, I'm concerned about the cost. Upon production, we should definitely work with suppliers to receive components at a far more discounted rate, something we didn't have to do for just making a prototype. Without this move, we'd barely be making pennies per machine. With it, we could actually make profit. |

Material |