Carpenter

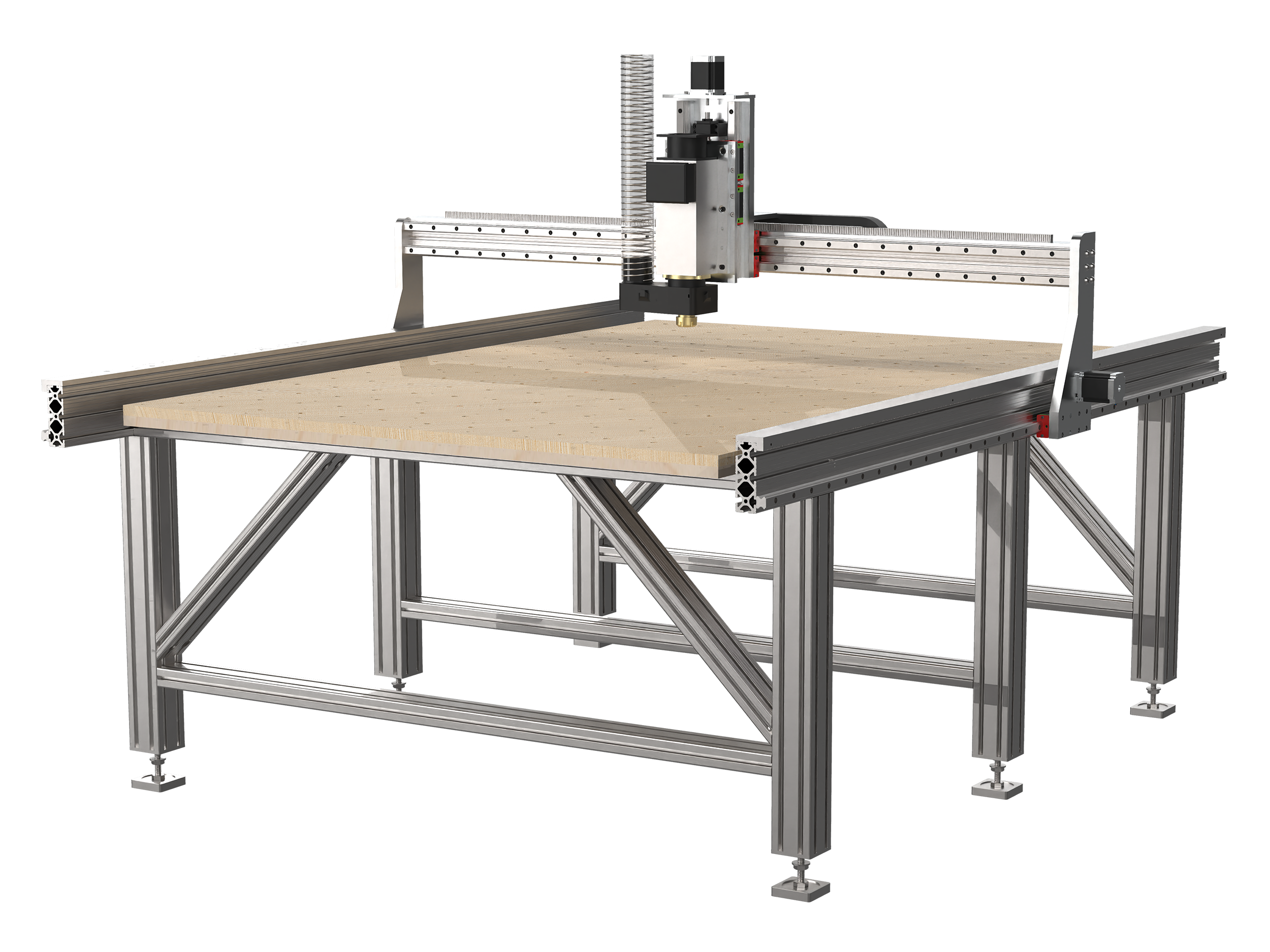

THE CNC COMPANY's first machine, a large-bed CNC router designed for softer materials like wood.

21' - 22'

SOLIDWORKS

CNC Manufacturing

Circuitry

Troubleshooting

Specs |

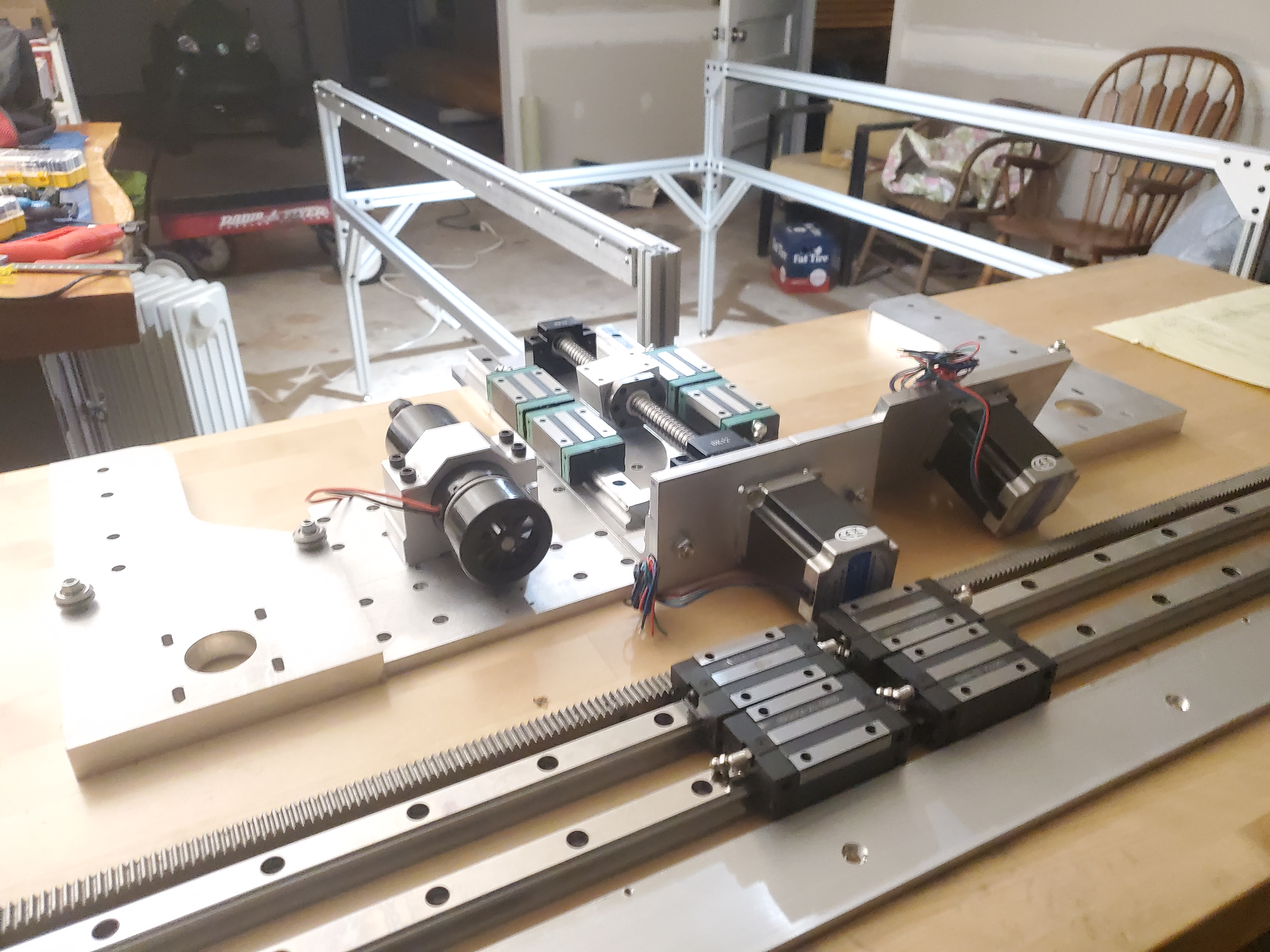

0.002 Precision 2x2' Min Work Area 5x10' Max Work Area 112 N Driving Force |

Contribution |

Carpenter was chiefly designed by Zack and Alex. Though I didn't CAD 9-5, I was involved in the entire design process and contributed to design of critical components such as the gantry upright, X axis linear motion, and drag chain/wiring. I worked heavily on manufacturing and assembly of the machine, contributing to manufacturing every single component, whether CNC machining, tapping threads, or soldering wires. I tested the machine, diagnosing racking issues, instability of the X axis, Z axis slipping, and more. |

Improvement |

With the resources we had,we honestly did a pretty good job. Most issues with Carpenter 1 (mainly rigidity) were resolved in Carpenter 2, but I do have some ideas of other ways the issues could've been solved which may or may not be better. Due to the machine's long X axis, we experienced some bending of the aluminum extrusions. The solution we went for was to add a third set of legs in the middle to support the load, but I think a potential simpler and cheaper soution would be to attach long diagonal braces from each leg to the middle. Diagonal braces would be less material and prevent dipping as well as racking. After some issues with V-groove in Carpenter 1, we opted for HGH rails in Carpenter 2, a move I don't totally agree with. The idea the rails come from the right place but I think it contradicts the machine's identity of being extremely cost-friendly. HGH rails are undoubtebly just better, but like hiring Nikola Tesla to fix your lightbulb, it's overkill. For Carpenter's purposes, V-grooves are just fine, and higher-end machines of the same category still use them. The improvements to rigidity should've solved issues with V-grooves experienced in Carpenter 1 especially if we use larger rails. |

Material |